LEWA Triplex Process Diaphragm Pumps: High-Pressure Aseptic Homogenization Solution

Hermetically tight, safe and reliable.

High-Pressure Aseptic Homogenization with LEWA Triplex Process Diaphragm Pumps

In industries like food, life sciences, and fine chemicals, homogenization is a crucial process step.

Sterility is paramount when handling sensitive fluids. With the reliable LEWA Triplex pump, hermetic tightness of the pump head chamber is assured, preventing emissions into the environment. Years of expertise in hygienic design ensure the highest production safety, even with delicate fluids. Precision metering ensures recipe conformity and repeatability.

LEWA's aseptic pumps can be qualified and validated with all necessary documentation to meet quality requirements. Additionally, they boast long service life and low life cycle costs.

Advantages of Opting for the LEWA Homogenizing Pump for High-Pressure Aseptic Homogenization

The LEWA triplex pump in hygienic design is ideal for homogenizing highly sensitive fluids, ensuring seamless production and efficient cleaning cycles.

Sterile processes through absolute asepsis

The pneumatically driven two-stage sterilizable homogenization valve guarantees sterility and thus a sterile process.

Hermetic tightness

The hermetically tight fluid chamber guarantees zero leakage from inside to outside and vice versa. This prevents access of atmospheric oxygen.

High process reliability for 24/7 continuous operation

The proven diaphragm operation with a typical diaphragm lifetime of 8,000 hours ensures uninterrupted production cycles.

LEWA triplex as the standard

The standard for aseptic process pumps is the robust and proven LEWA triplex pump series.

Years of experience with sterile applications

With sanitary and hygienic designs, LEWA gained many decades of experience in the hygienic of pump heads and valves in the food, pharmaceutical and life science industries.

LEWA is pleased to offer a customized pipe analysis on the suction and discharge side as a service.

LEWA's triplex series is characterized by very low-noise operation and a low-pulsation flow rate. This is made possible by the even piston offset (eccentric offset). As an option, it is possible to install hygienic pulsation dampers in the piping system.

Food safety & compliance

Due to their design, pumps of the LEWA triplex series ensure a high production and thus quality safety for food and at the same time the conformity with applicable regulations on hygienic standards.

Excellent cleanability

To ensure food safety, regular cleaning is important. Cleaning and sterilization of LEWA triplex pumps is done very easily, thus cleaning times can be reduced significantly.

Process Pump Features for High-Pressure Aseptic Homogenizing

Configuration for especially critical processes

For processes that require a particularly sterile environment, such as in the pharmaceutical industry, your pump can be designed accordingly.

Individual design

The pump is designed according to your specific requirements.

Mounting of different homogenizing valves possible

If you have specific requirements regarding the homogenizing valve, this request is easy to realize, since LEWA triplex pumps can be equipped with various customer-side homogenizing valves.

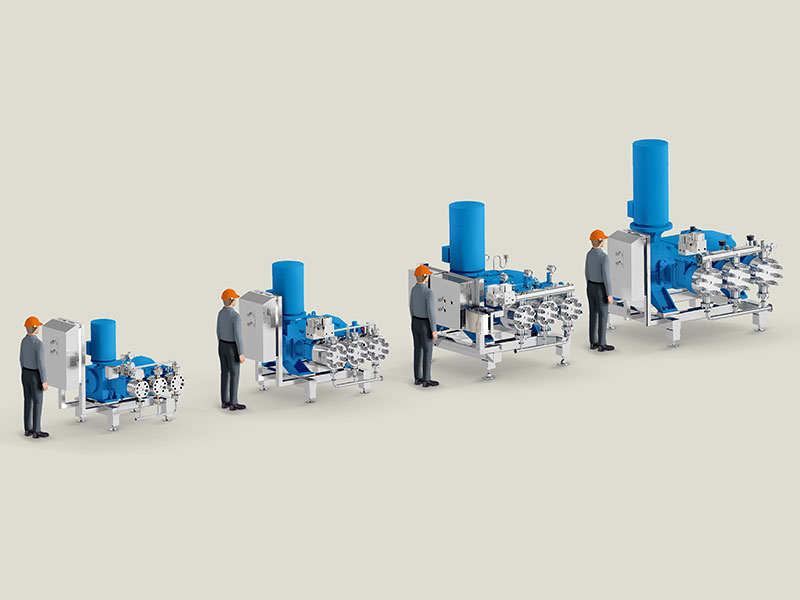

Production scale-up possible

A scale-up of the whole process is easily achieved without any problems by the various sizes of LEWA triplex pumps. This is accomplished without changing the essential functional characteristics of the pump and its cleanability.

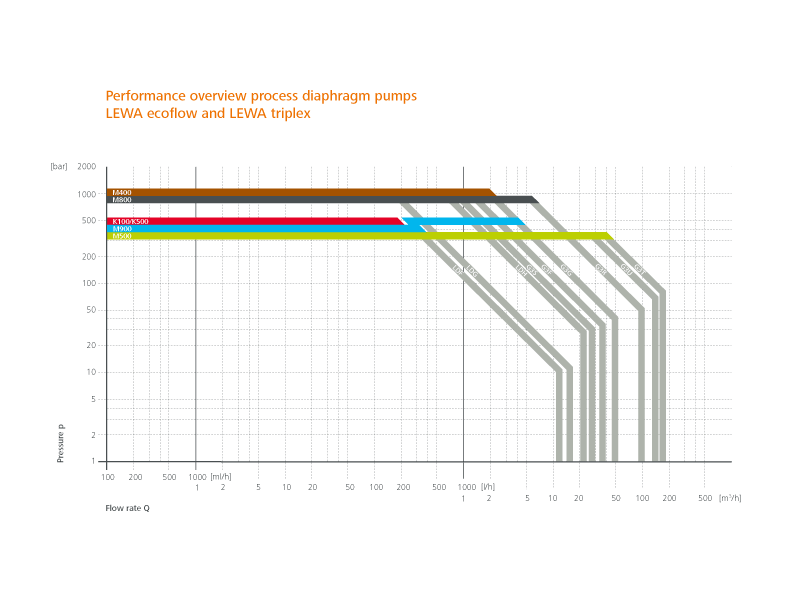

Performance data

| Type | Flow rate [l/h] | CIP rate [l/h] * | Discharge pressure [bar] |

|---|---|---|---|

| Pilot plant G3S | 500 -1,000 | 1,000 | 450-500 |

| Option 1 G3F | 5,000 | 5,000 | 280 |

| Option 2 G3G | 10,000 | 10,000 | 250 |

| Option 3 G3M | 15,000 | 15,000 | 290 |

| Option 4 G3R | 18,000 | 18,000 | 300 |

*) An external CIP pump cleans the entire system and thus also the homogenizer according to the overall applicable cleaning requirements. This results in the actual CIP rate.

Industries

Bombas y soluciones de dosificación para la industria química

Cuando en procesos de alta presión deben transportarse o dosificarse fiablemente suspensiones y fluidos críticos, peligrosos para el medio ambiente, tóxicos o inflamables, no hay alternativas frente a las bombas dosificadoras, bombas de membrana de proceso y sistemas de dosificación sellados herméticamente de LEWA. Las bombas selladas herméticamente de LEWA con presiones de hasta 1200 bar son la mejor opción para la fabricación de productos químicos intermedios y finales. ¡Póngase en contacto con nuestros expertos y permítanos asesorarle acerca de soluciones individualizadas con bombas o sistemas para aplicaciones químicas!

More DetailsBombas y sistemas para las industrias farmacéutica, de ciencias biológicas y de biotecnología

Como fabricante líder de bombas y sistemas para las industrias farmacéutica, de ciencias biológicas y de biotecnología, LEWA le da soporte durante el desarrollo de soluciones completas que satisfacen con precisión los requerimientos de su proceso. En la fabricación de productos farmacéuticos se requieren conocimientos especiales para garantizar que se cumplan los requisitos legales. Nuestra principal prioridad es la fiabilidad en lo relativo a la producción, documentación y validación.

More DetailsBombas y sistemas para la industria alimentaria y de bebidas

LEWA facilita bombas y sistemas para la homogeneización y dispersión a las empresas productoras y constructoras de plantas de la industria de alimentos y bebidas, así como para otras operaciones de procesamiento en la industria alimentaria. Trabajamos con usted para planificar todas las operaciones técnicas fundamentales de los procesos, como por ej. transporte, dosificación, mezcla, calefacción y refrigeración, para que pueda procesar su producto crudo con eficiencia de costes.

More DetailsApplications

Producción farmacéutica

Las bombas y sistemas de dosificación deben cumplir los siguientes exigencias la producción de.

More DetailsMedición química en sistemas de limpieza a alta presión.

Las bombas de diafragma de proceso y dosificación LEWA satisfacen las demandas específicas para la producción de melamina (trimerización de urea). ¡Consúltenos!

More DetailsSecado por atomización farmacéutico

LEWA proporciona bombas dosificadoras de diafragma precisas y eficientes para el secado por atomización farmacéutica. ¡Consúltenos!

More DetailsFabricación de mantequilla

Para garantizar una calidad constante de la mantequilla untable, se dosifican ingredientes tales como aceite de colza, agua y salmuera de manera flexible y completamente automática con bombas ecoflow.

More DetailsHomogeneización de la leche

Con los sistemas de homogeneización LEWA, los productores de productos lácteos pueden lograr un tamaño de partícula, humedad y color uniformes, por ejemplo, en la fórmula infantil, y evitar que el concentrado de leche dentro de él se mezcle.

More DetailsSistemas de alta pureza

Las bombas y los sistemas de alta pureza de LEWA son una solución probada en la industria farmacéutica y biotecnológica. Nos complace ayudarlo con su sistema individual de alta pureza.

More DetailsDownloads

LEWA Lösungen für die Öl- & Gasindustrie. (DE)

High-end Dosier- und Prozesspumpen sowie Systeme und Packages für spezifische Funktionalitäten zum Einsatz in der On- und offshore Förderung.

4 MB

| pdf |

18.10.2022

LEWA Solutions for the Oil & Gas Industry. (EN)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

18.10.2022

LEWA process diaphragm pumps LEWA triplex and LEWA ecoflow for process engineering. (EN)

LEWA process diaphragm pumps set the standard for process engineering, allowing even critical, toxic, or flammable fluids to be conveyed safely.

4 MB

| pdf |

18.02.2022

LEWA process diaphragm pumps LEWA triplex and LEWA ecoflow for process engineering. (USA)

LEWA process diaphragm pumps set the standard for process engineering, allowing even critical, toxic, or flammable fluids to be conveyed safely.

4 MB

| pdf |

18.02.2022

LEWA Prozess- Membranpumpen LEWA triplex und LEWA ecoflow für die Verfahrenstechnik. (DE)

LEWA Prozess-Membranpumpen setzen den Standard in der Verfahrenstechnik. Mit ihnen können selbst kritische, toxische oder brennbare Flüssigkeiten sicher gefördert werden.

4 MB

| pdf |

18.02.2022

Soluciones de LEWA para la industria del petróleo y gas. (ES-SA)

Bombas de dosificación y de proceso de alto nivel, así como sistemas y paquetes para funciones específicas para su uso en producción tanto en la tierra como en el mar.

3 MB

| pdf |

18.02.2022

LEWA Solutions for the Oil & Gas Industry. (USA)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

06.11.2022

Remote Head Konstruktionen für LEWA Pumpen

LEWA Remote-Heads. Entkoppelung vom Verdrängersystem für mehr Sicherheit.

1 MB

| pdf |

18.02.2022

Remote Head Designs for LEWA pumps

LEWA remote heads. Disconnecting from the displacement system for more safety.

1 MB

| pdf |

18.02.2022

D6-103_LEWA_Homogenisator_Testsystem_en.pdf

LEWA homogenizer test system

361 KB

| pdf |

07.03.2024