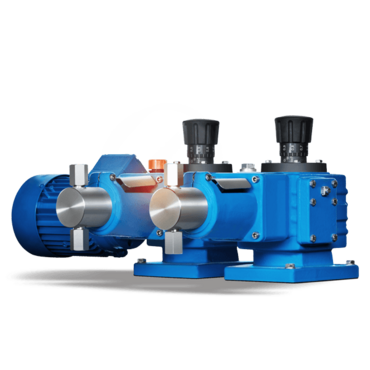

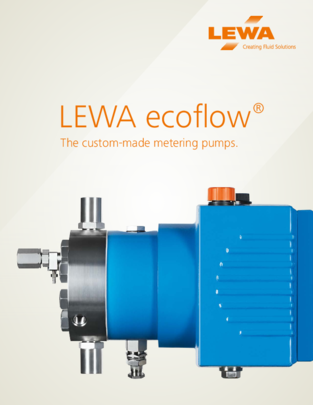

LEWA ecoflow®packed plunger metering pump

The cost-efficient alternative for simple metering tasks.

In many scenarios, using complex diaphragm metering pumps isn't always the most cost-effective option for pumping simple fluids. That's why we offer the LEWA ecoflow packed plunger metering pump as a cost-efficient alternative.

For metering non-critical fluids like water or resin, relying on a simple and robust pump with low acquisition and operating costs is advantageous.

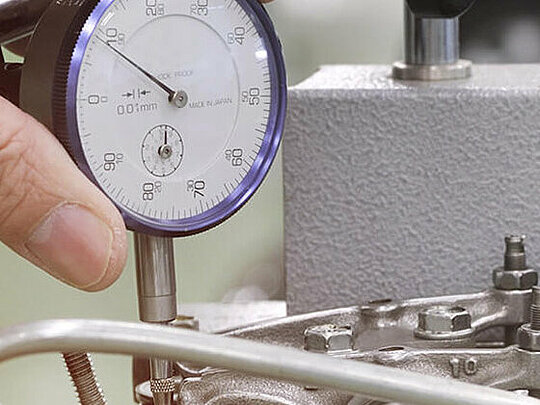

Despite its affordability, we uphold the trusted LEWA quality: Each ecoflow packed plunger metering pump is manufactured in Germany and undergoes rigorous quality assurance. Additionally, we offer a versatile modular system with various pump heads, drive units, and motors.

Discover the Advantages of Choosing LEWA ecoflow® Packed Plunger Metering Pump

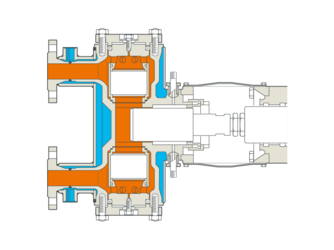

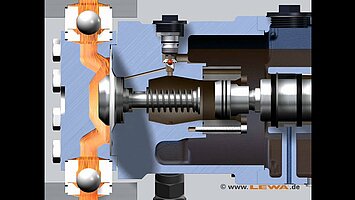

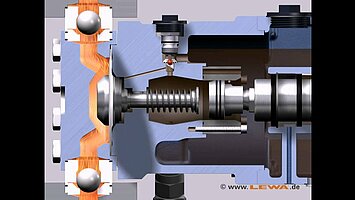

The LEWA ecoflow stands as a hydraulically actuated packed plunger metering pump, offering distinct advantages compared to similar pumps.

Unique suction capability

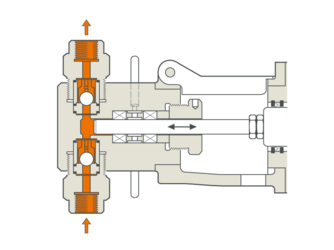

The LEWA ecoflow packed plunger metering pump differs from other pumps due to its unique suction capacity. With an absolute suction pressure of up to 0.1 bar, it not only provides a wide array of safe installation options. The operating costs for the entire system can also be lower than with comparable pumps.

Economical solution for simple tasks

Through the simple but robust plunger technology of the pump head, the ecoflow packed plunger metering pump is the ideal pump for easy metering tasks with non-critical fluids. In addition, it features particularly high energy efficiency and is low maintenance.

API 675‐Standard

The ecoflow series fulfills the internationally valid quality standard of the American Petroleum Institute API 675. It includes all definitions for a diaphragm metering pump in industrial use in terms of its design, construction, performance and acceptance test.

High-quality materials

All pump parts in direct content with the fluid are made from high-quality materials. Plungers, for example, are made from ceramic oxide.

Worldwide standards

When designing pumps, we adhere to globally valid standards such as VDMA 24284, 24286‐10 and FDA guidelines.

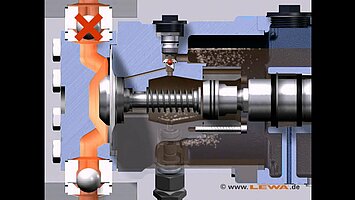

Tried-and-tested plunger seal

The LEWA ecoflow packed plunger metering pump uses the tried-and-tested LEWA plunger seals for maximum tight sealing.

Explore Videos Featuring LEWA ecoflow® Packed Plunger Metering Pump

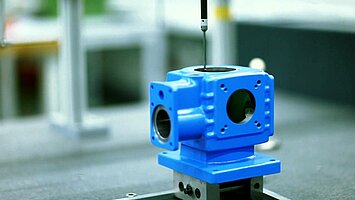

LEWA Creating ecoflow

Typical production of a LEWA ecoflow diaphragm metering pump in the production plant in Leonberg, Germany. Covers the full cycle from parts production to quality control, assembly, testing and shipment.

LEWA Creating ecoflow

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – complete animation

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – snifting valve

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – pressure relief valve

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow - multiplex drive element

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

Uncover Key Features of Packed Plunger Metering Pumps

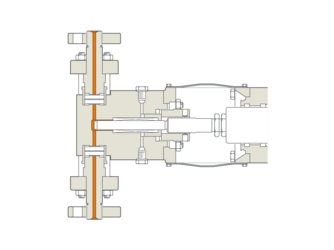

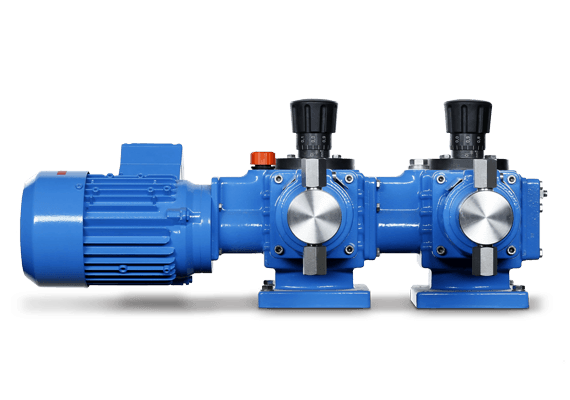

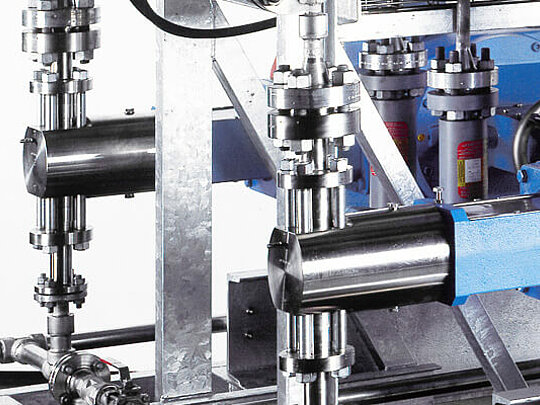

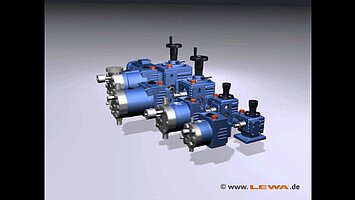

Multiplex capability

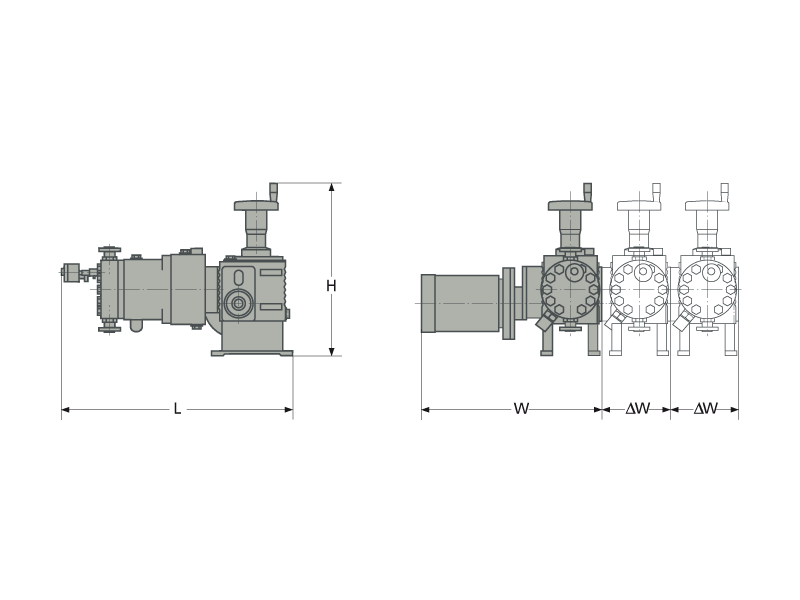

Single drive units with vertically installed motor are space-saving. Alternatively, multiple drive units with identical or different output can be combined for pulsation reduction or recipe metering.

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Heating and cooling jackets

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Diverse connection geometries

Our pumps are equipped with all common connection geometries such as DIN standard, BASF's high-pressure standard, American ANSI, JIS, or your individual requirements. Customized configurations are possible.

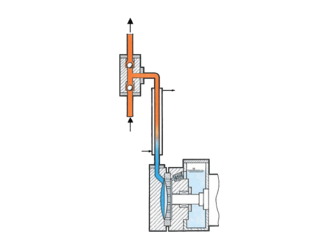

Plunger seal with flushing possibility

In order to guarantee a long-life pump and leak-free operation, our pumps have a flushable plung seal. Thus, leaks are removed easily and safely.

Diagnostic connection

Our pumps and systems have connections that facilitate the diagnosis of their performance. This is done by a service technician on site or via remote monitoring.

Integration into process control systems

The signal acquisition of process control systems is achieved analogously or digitally. Flow rate is adjusted via electric or pneumatic stroke adjustment, alternatively by motor drive (FU).

Intellidrive technology

Using the highly-dynamic servomotor, you can adjust the stroke of the pump to the requirements of your system and your process.

Special design materials

If the process demands it, wetted parts such as pumps heads and valves will be made of special materials such as stainless steel 316/316L (1.4401/1.4404), Hastelloy or Duplex steel and PVC.

Browse Our Diverse Range of Packed Plunger Metering Pumps

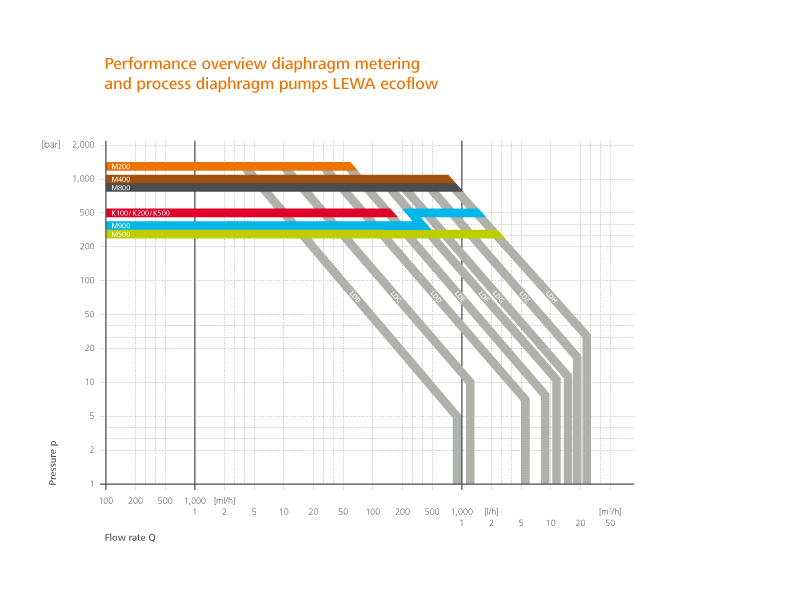

With a range of pump head options, the LEWA ecoflow plunger metering pump offers versatile performance capabilities. This enables us to deliver high-performance, energy-efficient pumps tailored to your specific application needs.

Explore Versatile Pump Head Variants for Packed Plunger Metering Pumps

Discover Our Range of Pump Heads Tailored for Packed Plunger Metering Pumps. Choose from All-Purpose Variants to Special Designs for High Temperatures, Pressures, or Aggressive Fluids.

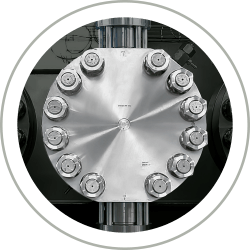

Pump head K110/K111

Standard pump head with single gland for pressures up to 160 bar.

| Type | K110/K111 |

| Pressure | 160 bar |

| Flow rate | 9 m³/h |

| Temperature | -70/+400 °C |

| Viscosity | 1.500.000 mPa∙s |

| Operational capability | Can be installed on all ecoflow pumps ≥ LDE. |

Pump head K210/K211

High-pressure pump head with double tensioned gland packing for pressures up to 500 bar.

| Type | K210/K211 |

| Pressure | 500 bar |

| Flow rate | 9 m³/h |

| Temperature | -70/+400 °C |

| Viscosity | 1.500.000 mPa∙s |

| Operational capability | Can be installed on all ecoflow pumps ≥ LDE. |

Pump head K511

Custom design with total heating jacket for melts.

| Type | K511 |

| Pressure | 176 bar |

| Flow rate | 1,5 m³/h |

| Temperature | -20/+150 °C |

| Viscosity | 100.000 mPa∙s |

Special pump heads in remote head design

Some tasks in process engineering include the metering or circulation of media with critical properties like high temperature and high abrasivity. These critical conditions frequently need to be kept away from the displacer system of the metering pump, either to protect the system or its operating personnel. A normal metering pump is not suitable for such tasks due to its compact design.

| Type | MR / MV / KV |

| Pressure | 500 bar |

| Flow rate | 19 m³/h |

| Temperature | -70/+400 °C |

| Viscosity | 100.000 mPa∙s |

| Operational capability | Remote pump heads can be installed on all LEWA ecoflow metering and process pumps and on all LEWA triplex metering and process pumps. |

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsWet oxidation of waste water

For wet oxidation and other processes, we recommend our tried-and-tested LEWA diaphragm pumps. Ask our experts for more information!

More DetailsPharmaceuticals production

Metering pumps and metering systems must meet the following demands of pharmaceutical production.

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsProduction of biofuels

Biofuels are produced using metering and process pumps from LEWA in the remote-head design. Learn more about these and other applications!

More DetailsFlue gas cleaning by means of metering sulfur | LEWA

When using an electrofilter for flue gas cleaning, metering sulfur improves the filtration efficiency. LEWA has the solution!

More DetailsProduction of gelatine

In the production of gelatin and in the fabrication of gelatin products, LEWA pumps and systems are used. We would be happy to give you more information!

More DetailsHigh purity systems

Pumps and high purity systems from LEWA are a tried-and-tested solution in the pharmaceutical & biotechnology industry. We are happy to assist with your individual high purity system.

More DetailsContinuous metering of extremely small quantities with LEWA intellidrive

Minimum flow rates down to 1 ml/h: With LEWA intellidrive technology, we already have created solutions for many applications with very small flow rates.

More DetailsSulfuric acid injection in copper heap leaching

LEWA process pumps are used to reinject sulfuric acid at 98% into the main pipelines that go to the heap leach sprinklers.

More DetailsEsterification

With LEWA process diaphragm pumps, as well as the NIKKISO Non-Seal canned motor pumps we offer the optimum solution for esterification.

More DetailsAdditive dosing for fuels

LEWA supplies both diaphragm metering pumps and process diaphragm pumps for additive dosing in fuels. We provide you with the right pump and advice for your application.

More DetailsSolutions for flavor and color metering in the confectionery industry

LEWA creates custom-made, complete solutions that are ready to implement in your applications.

More DetailsDownloads

LEWA Lösungen für die Öl- & Gasindustrie. (DE)

High-end Dosier- und Prozesspumpen sowie Systeme und Packages für spezifische Funktionalitäten zum Einsatz in der On- und offshore Förderung.

4 MB

| pdf |

18.10.2022

LEWA Solutions for the Oil & Gas Industry. (EN)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

18.10.2022

LEWA ecoflow maßgeschneiderte Dosierpumpen (DE)

LEWA ecoflow ist ein umfangreiches Baukastensystem für Membran- und Kolbenpumpen. Es kombiniert sieben Triebwerksgrößen mit sechs unterschiedlichen Pumpenköpfen.

3 MB

| pdf |

18.02.2022

LEWA ecoflow bombas dosadoras customizadas (PT)

A ecoflow LEWA é um extensivo sistema modular para bombas dosadoras de diafragma e de pistão.

Ela combina sete tamanhos de unidade com seis diferentes cabeças de bomba.

3 MB

| pdf |

18.02.2022

LEWA ecoflow custom-made metering pumps (EN)

LEWA ecoflow is an extensive modular system for diaphragm and packed plunger metering pumps.

It combines seven drive sizes with six different pump heads.

3 MB

| pdf |

18.02.2022

Soluciones de LEWA para la industria del petróleo y gas. (ES-SA)

Bombas de dosificación y de proceso de alto nivel, así como sistemas y paquetes para funciones específicas para su uso en producción tanto en la tierra como en el mar.

3 MB

| pdf |

18.02.2022

LEWA Solutions for the Oil & Gas Industry. (USA)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

06.11.2022