Solutions

A pump for the heat.

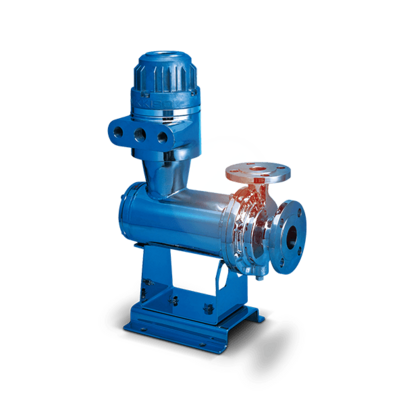

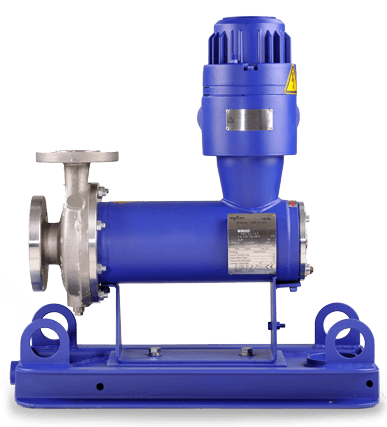

With the NIKKISO Non-Seal canned motor pump, LEWA offers a suitable solution for the various requirements and customer processes.

Advantages of the NIKKISO Non-Seal canned motor pump in use as a heat transfer pump:

- Twin protecting shell: The special structure of the canned motor pump prevents leakage of the metered medium to the atmosphere, even in the unlikely event of damage to the can

- No cost- and repair intensive dynamic seals: The lack of a dynamic seal significantly increases the mean time between failures’ values and therefore plant safety

- Due to the special design without shaft seal and the fluid-lubricated plain bearings, costly and maintenance intensive lubrication systems are not required.

- No shaft alignment necessary because of the integral, compact design. A mechanical coupling and coupling guard are thereby eliminated

- Very low noise level thanks to the lack of coupling, the usual ball bearings for motor bearing and the motor fan

Background

Heater and pump are the heart of the heat transfer circuit.

Heat transfer oil plants are used to indirectly temper processes in production. In these plants, a fluid – such as thermal oil – is utilized to transfer heat. The thermal oil makes it possible to heat or to cool objects or substances during a process. Unlike the use of water as a heat transfer medium, thermal oil can be used to guarantee system operation up to 350°C, even without pressure. In addition, there is neither corrosion nor the danger that the plant could freeze in an outdoor installation.

The heat transfer technology comprises together with the heat transfer oils a very wide range of production processes. The oils are on a mineral or synthetic basis, and can be heated up to 450°C. At such high temperatures, this happens at a pressure of about 12 bar. Typical applications for the canned motor pump include circulation pump the chemical, petrochemical, refinery and energy utilities. Thus, the pump forms the core of a single heat transfer circuit, which is used for indirect temperature control.

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsProducts

NIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More Details