Solutions for Carbon capture storage with LEWA process pumps

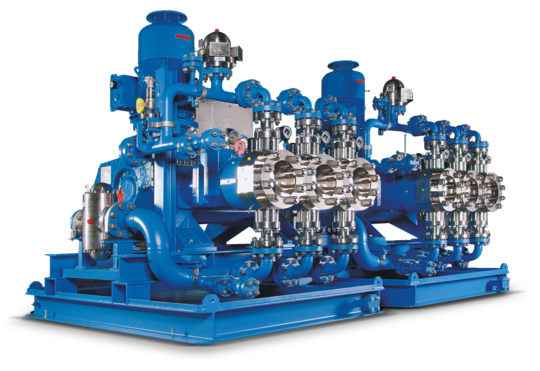

Conventional pump systems, such as piston or centrifugal pumps, can be reliably operated for the injection of hydrogen sulfide/carbon dioxide only by using expensive additional measures. Process diaphragm pumps from LEWA are a reliable solution for these pumping tasks up to outputs of 1000 kW. If two coupled pumps running in parallel are used, this extends to well above 1000 kW.

H2S (acid gas) is an extreme challenge for pump systems:

- It is very toxic, highly flammable and hazardous to the environment

- It has poor lubrication properties

- It has a high vapor pressure

The most important properties of the LEWA process diaphragm pumps for critical applications such as CCS are:

- Hermetically sealed

- Previously implemented flows up to 110 m3/h

- Dry run safe

- High efficiency even in partial load

- Diaphragm monitoring system by default

- Online and offline condition monitoring systems

- Flexibility due to speed control

- Variable compositions of material flows and variable back pressures possible

- Conveying fluids containing solid content is possible

- High operational safety and availability

- Long diaphragm service life

- Low maintenance costs

- Low lifecycle costs

To optimize the energy efficiency in the CSS compression all during the injection a combination of compressors and process diaphragm pumps is recommended.

Read more in our technical article

CCS Compression with compressors and process diaphragm pumps

Background for H2S (acid gas)

Process description

Hydrogen sulfide is a compound of sulfur and hydrogen with the chemical formula H2S. It is flammable, colorless, toxic, and smells like rotten eggs. It is a weak acid, whose salts are sulfide and hydrogen sulfide.

In nature, hydrogen sulfide occurs as a very variable component of natural gas and crude oil, as volcanic gas, and in spring water. It also results from rotting and decomposition processes during the breakdown of biomass, at waste disposal sites, or in high pressure wastewater pipelines.

Source: Wikipedia, February 2012

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsProducts

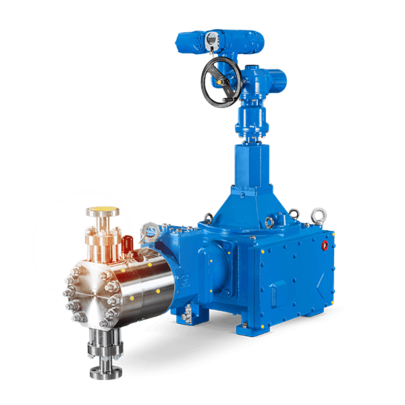

LEWA ecoflow®: The Leading Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

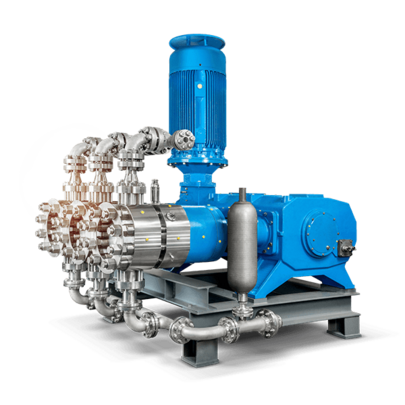

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

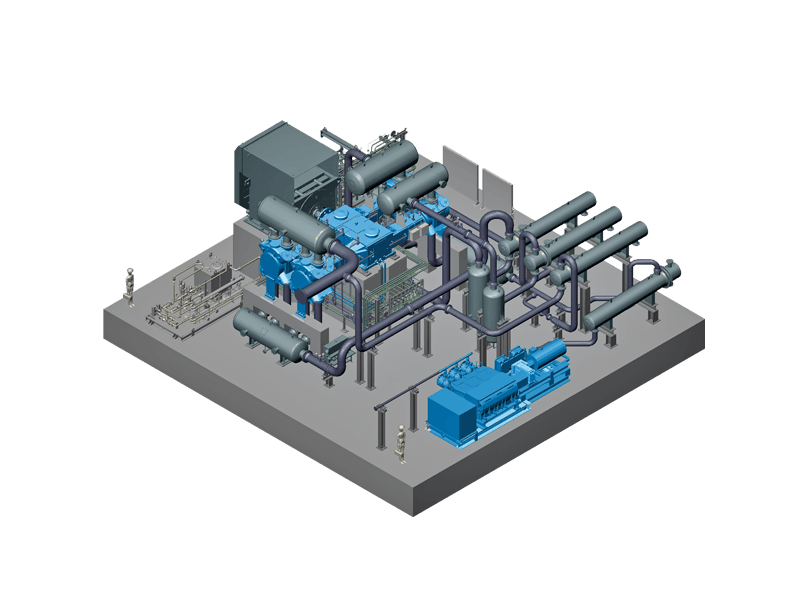

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More Details