Solution

For metering ingredients in butter production LEWA offers the following solution:

- Food industry proven LEWA ecoflow or hygienic/sanitary guarantees consistent product quality of various types of butter

- Due to hygienic and efficiency reasons, butter production facilities run on a highly automated level. Since LEWA pumps with their patented M9 technology are highly reliable, nearly maintenance-free, and robust, the process chain barely has to be stopped. The probability of default is extremely small.

- If a diaphragm change is necessary, it can be done quickly and easily

- Even during long running times, which are normal in butter production, the pumps have an accuracy of ± 1 percent

- Due to combination of frequency control and electric stroke adjustment, the pumps can run automatically and flexibly over a wide adjustment range. Thanks to the multiplex technology, various metering tasks can be combined efficiently.

- All materials are suitable for handling foods: e.g. in order to avoid corrosive effects of brine on seals of valves, special materials like Gylon® are used. Furthermore, a trusted supplier delivers PTFE, the material for LEWA’s pump diaphragms. The whole production is monitored continuously by LEWA. Of course, the PTFE is compatible with biological tissues.

- Minimal dead space and smooth stainless steel surfaces 316/316L (1.4401/1.4404) inside the pump facilitate CIP cleaning.

Background

How is butter produced and which kinds exist?

Butter is made from pasteurized cream. Therefore, milk is skimmed in a centrifugal separator within a few seconds. Afterwards, the cream is pasteurized and stored for about 20 hours. In the butter churn, which is comprised of a rod, a cylinder, and a kneader, the cream is beaten, and the butter is separated and kneaded. Then the butter is molded in a molding machine and packaged. In order to make 1 kg of butter, approximately 22 liters of milk are necessary. A byproduct of buttering is butter milk.

There are various types of butter:

Butter made from a fermented cream is known as cultured butter. The aroma that is created through the process gives butter a fresh and nutty taste. Sweet cream butter is made from unfermented cream. To get mild-soured butter, lactic acid is added to fresh cream butter after buttering.

All categories of butter are sold in both salted and unsalted forms. Either granular salt or strong brine are added to salted butter during processing. In addition to enhanced flavor, salt acts as a preservative. For the production of spreadable butter vegetable oil is often incorporated in butter.

Industries

Pumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

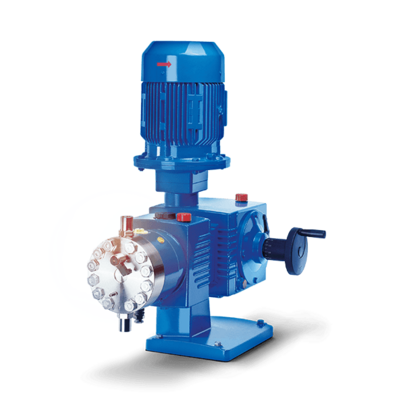

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Advanced Hygienic Diaphragm Metering Pumps for Sanitary Applications

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

More DetailsLEWA triplex®: High-Pressure Homogenizing Process Pumps

The LEWA triplex homogenizing pump utilizes hermetic diaphragm technology, making it ideal for sensitive applications such as ready-to-drink products, infant food, nutraceuticals, and enteral nutrition. Designed to handle demanding fluids, it finds optimal use in the food, beverage, and pharmaceutical industries.

More Details