Your individual solution for downstream processing

LEWA delivers diaphragm metering pumps and complete metering systems to handle all types of downstream processing. Examples include gradient mixers for producing gradients and customized systems for inline dilution of buffers as well as metering stations.

These solutions provide the following advantages:

- Precise flow rates (incrementally or linearly variable, 1-99%)

- Reproducible and highly accurate positioning (0.5%)

- Hermetically tight system concept in downstream processing

- Very large reproducible adjustment range of the pump/system

- High availability, reliability and process safety

- Reliable for validation thanks to high precision in downstream processing

- Ability for inline cleaning and damping (CIP/SIP), optionally ventable

- Hygienic pumps available (wetted electropolished, ASME-BPE, EHEDG certified)

- Versions available for installation in clean rooms

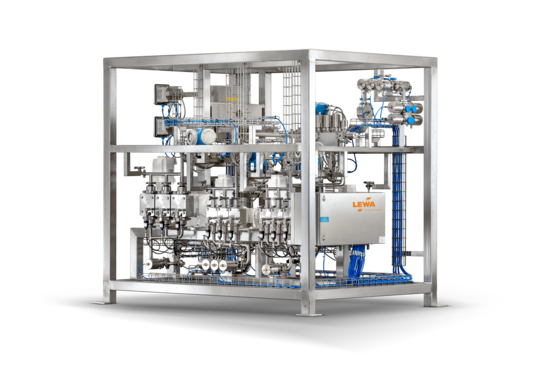

- Design as a complete skid with all process-relevant attachments for integration into chromatography systems is possible

- Comprehensive documentation for qualification and validation

- IQ/OQ/PQ support

- Ex protection at the request of the customer

Areas of application

Areas of application: LEWA metering pumps, metering systems and gradient mixers are used in downstream processing, including in the following areas:

Low- and medium-pressure chromatography, for example

- Preparative liquid column chromatography

- Normal- and reversed-phase chromatography

- Ion-exchange chromatography

- Affinity chromatography, etc.

- Downstream processing for purifying vaccines, innovative therapeutic proteins, monoclonal antibodies, hormones and blood plasma products

High-pressure chromatography

- High-pressure liquid chromatography (HPLC)

- Preparative countercurrent chromatography with supercritical CO2 using SFC (supercritical fluid chromatography)

Get in touch today so that we can talk about a strategy for implementing your downstream processing requirements!

Background: Process description of downstream processing

Liquid chromatography is the most important part of the purification process and provides a broad range of physical downstream processing methods for separating complex mixtures of substances.

The components to be separated are divided into two phases: The stationary phase in a column and the mobile phase, which flows through the stationary packing (here, liquid).

How does chromatography work?

A mixture of various components of a liquid/gas enter a process of process chromatography. The goal is to purify the mixture (downstream processing). The various separating and chromatography solutions are pumped through the system at various speeds. The interaction between the stationary and mobile phases in the system varies in intensity, causing the mixture of substances to separate. The lower the affinity of a molecule for the stationary phase is, the shorter the time in a chromatography column is, and vice versa.

Why is chromatography so special and important?

The chemical and bioprocess industries have the need to separate one product from a complex mixture and to eliminate impurities. This is an important step in the entire processing chain (downstream processing / cleaning) to produce a product with the required level of purity. Today there exists a broad range of methods that the industry can use to achieve these goals. For many reasons, chromatography is a very special and selective separation method that has been used for decades—primarily in the area of production. First, it can separate complex mixtures with great precision. Even very complicated molecules such as proteins, for instance, can be carefully separated from each other using chromatography. This way, basically any soluble or volatile substance can be purified if the correct adsorbents, carrier fluids / mobile phases are used and provided that process parameters are adapted and monitored (temperature, pH value, flow velocity, conductivity and much more).

Downstream processing is perfect for separating or purifying sensitive products from the pharmaceutical sector specifically.

Industries

Pumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsProducts

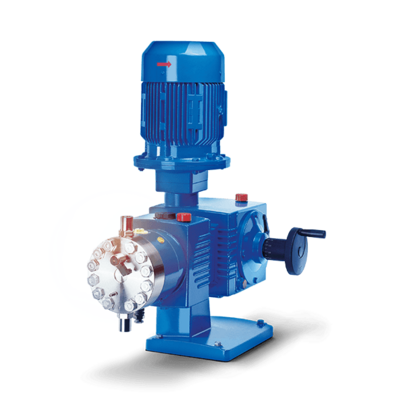

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

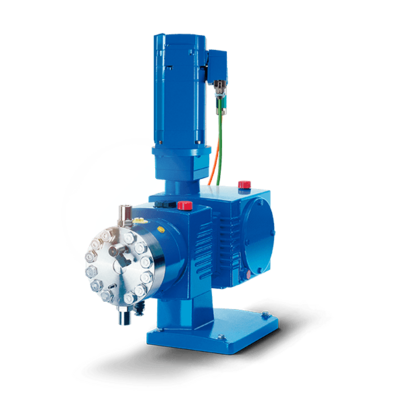

More DetailsLEWA ecoflow®: Advanced Hygienic Diaphragm Metering Pumps for Sanitary Applications

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

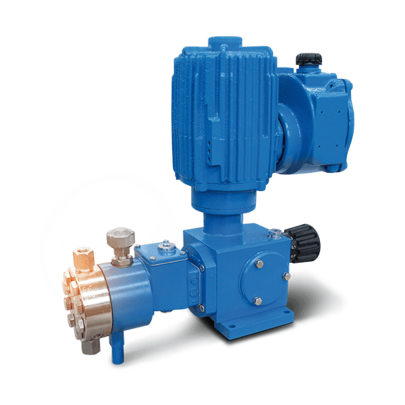

More DetailsLEWA ecodos®: Advanced Sanitary/Hygienic Diaphragm Metering Pumps for Precise Fluid Control

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

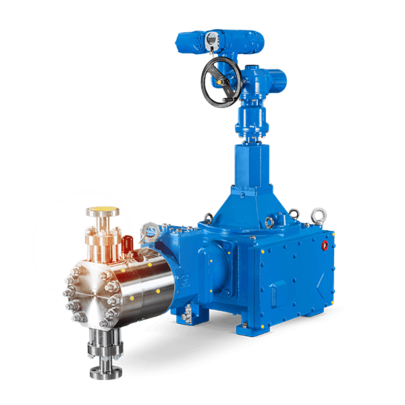

More DetailsLEWA intellidrive®: Cutting-Edge Diaphragm Metering Pump Technology for Precision Fluid Management

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps for Advanced Research Applications

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

More DetailsLEWA ecoflow®: The Leading Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details